Our guide to different types of wood veneer and how they are used

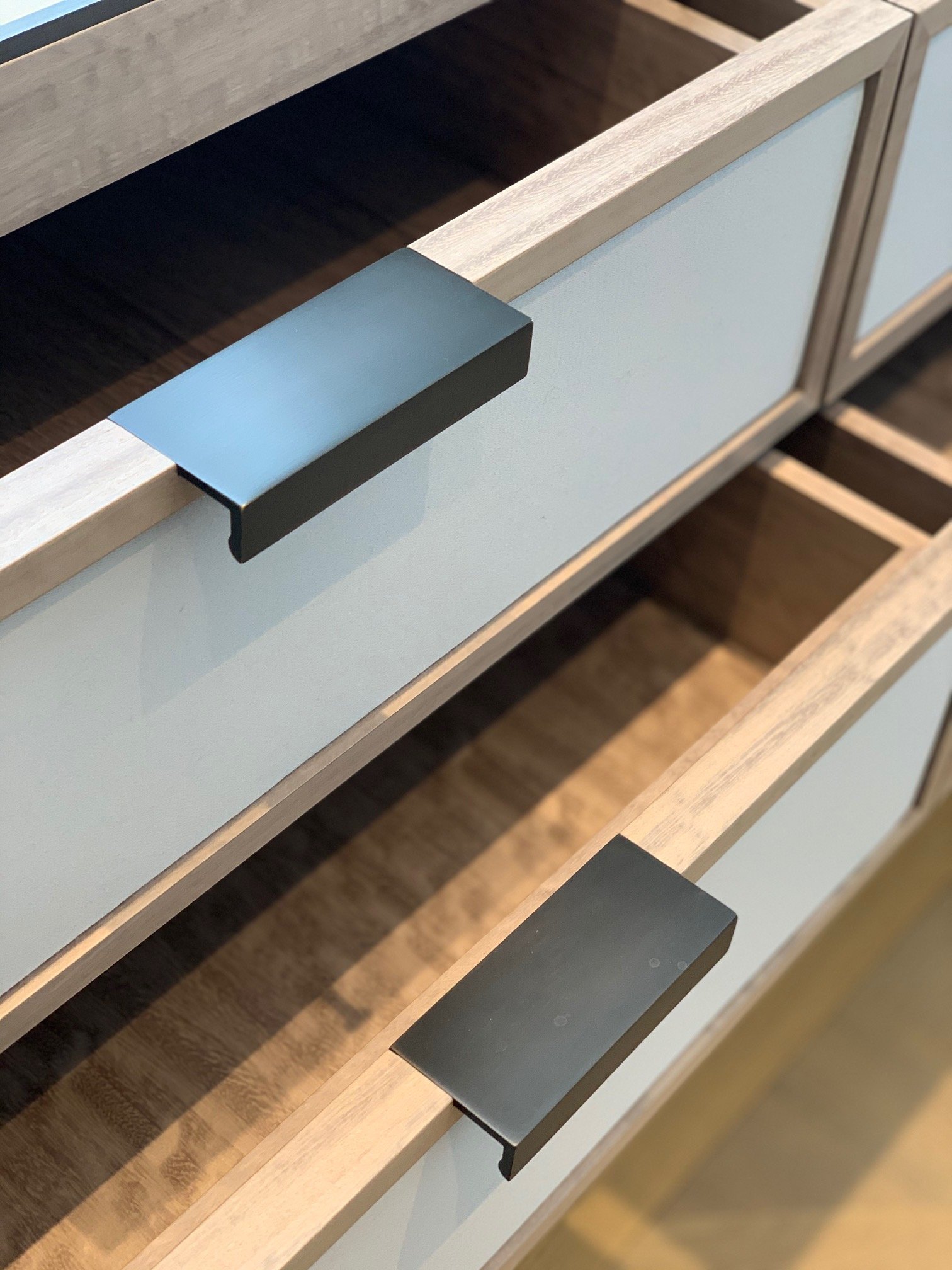

Our beautiful bespoke timber furniture and joinery is a mixture of solid wood and wood veneers. Here, we’re going to look at the different types of wood veneer and how we use them to create our unique interiors.

What is a wood veneer?

A veneer is simply a very thin ‘slice’ of real wood, which is then fixed to a base layer. The base layer is chosen for its stability, density, and its suitability for a particular purpose. Veneers provide amazing timber looks and style and use real wood in an eco-friendly manner, rather than the extravagance of solid timber. The veneers we source are chosen according to their surface appearance and their suitability for the item of furniture we’ve designed. Veneers are used for straight joinery – generally, within carcasses or for doors and flat surfaces, it cannot be profiled.

It's important to remember that a veneer is chosen for its practicality, as well as its appearance. A veneer can look the same as a solid piece of timber but is less vulnerable to the possibility of movement due to temperature changes, and is easier for our craftsmen to work with, too. As a single log will be cut into many slices, it means that each slice of veneer has a similar pattern and colour, so can be colour-matched and book-matched across larger areas, for instance for a run of wardrobe doors. Veneers come in varying thicknesses, from 0.6mm to 2.5mm. The thinnest veneers are cut into ‘leaves’ which are sewn together with transparent threads and glued onto extremely stable boards which are then processed into sheets to be used for furniture-making. The flooring industry also uses veneer processes to create engineered wood flooring. It’s a highly technological process that has been developed over many years to produce long-lasting, beautiful products. The thicker veneers (such as 2.5mm +) are used for flooring and for timber work surfaces.

A wood veneer dining table will always look spectacular, depending on the way the veneer is cut and matched, but it must be a suitable thickness too – around 3.5mm – to enable repairs to be made in case of damage. A piece of furniture or fitted cabinets made using veneers is every bit as special and decorative as something made from solid timber. Using veneers allows designers to be creative, using marquetry skills and different coloured and patterned veneers to embrace unique patterns and effects.

What types of wood veneer are there?

There are many different timber types, such as walnut, oak, ebony, maple and wenge – these are the more well-known timbers, but there are a host of exotic and tropical hardwoods that are also used. Traditional and antique furniture often uses veneers, such as birdseye maple, pippy oak and chestnut burr. We choose a wood veneer finish to suit the project, so we may show our clients several different veneers before we design a particular piece of furniture. Oak veneer is a classic choice, often used in combination with other materials. Walnut is a popular choice; the darker tones look elegant and contrast well with lighter finishes.

How many types of wood veneer are there?

There are endless types of veneers, as veneers are also described by the finish and treatment they’ve had after production. So, although all veneers are basically thin slices of wood, they can be stained or treated to create different looks. There are suppliers that will dye their veneers to order. That process means that a chosen veneer can then be dyed to a particular unique shade specified by the designer or architect. Coloured veneers, such as those from Mundy Veneer, come in all sorts of shades, from reds to yellows, blues and greys. We also sometimes use engineered veneers, where textures and patterns are printed on top of plain veneers.

Which wood veneer is best?

We have our favourites, naturally, but it’s difficult to pin down a ‘best’! We have wood veneers that we have used many times, because our designers know that the appearance will be consistent yet unique across the entire order. European Oak and American Walnut are always popular choices, thanks to their natural grain and characteristics. Any item of wood veneer furniture we produce will be individually designed and produced by our Joinery team.

How is a wood veneer made?

Manufacturing veneers is a specialised process, carried out in sawmills and factories, depending upon the type of veneer. Our design and joinery teams use veneer panels, which are specifically designed for furniture making, and supplied already fixed to the baseboard – so it looks just like a solid piece of timber. There’s a rotary cut method of manufacturing, as well as a horizontal slicing method. The rotary method is a way of slicing off a super-thin layer of wood from a rotating log and is a method popular for obtaining oak, pine and birch veneer. There are different terms for different cuts. Crown cut veneers show radial circles revealing the age of the tree, Quarter cut veneers avoid the ‘core’ of the tree and are more linear in pattern, Radial cut veneers are similar to Crown cut veneers. More complex veneer processes include Quilting and Crosscut, both produce beautiful, patterned looks.

How do you clean a wood veneer?

Most of our furniture that’s made from wood veneers has a protective polyurethane lacquer finish, which means that the colour and finish, whether it’s satin, matt or polished, will stay the same. Our veneered finishes should be dusted regularly with a soft cloth and can be polished if required, using a polish which we would suggest according to the type of veneer used. Wood veneers are often used for kitchen cabinet doors, and a wood veneer kitchen can be treated as a normal kitchen - regular spills and marks can be cleaned up with a soft damp cloth, and harsh chemical or abrasive cleaners should be avoided.

We consider veneers to be a luxury choice, allowing our design team to be creative with colour, texture and finish. All the veneers we use are from FSC approved sources.